The automatic cream & paste filling machine adopts programmable logic controller (PLC) human machine interface (HMI) technology, equipped with the imported photoelectric track switch from Korea, which is suitable for filling ointment products in the industries such as ointment, oil products, syrup, flavoring paste, fruit juice and etc. The filling nozzle will be automatically inserted into the bottle to carry out the filling and then rapidly ascend, which can reduce the bubbles. The product integrates electric and pneumatic functions into one, with reasonable design, stable performance, accurate quantity, glass table surface, automatic bottle feeding, steady operation without noise, electronic speed control of the filling speed and filling volume and convenient disassembly and cleaning. The new type filling equipment is the best choice for the realization of automatic production.

Characteristics:

1. The automatic bulls servo motor filling machine widely used in all kinds of liquid, viscous body, paste, filling valve can be replaced (then became automatic filling machine for thick sauce), also can fill particles semiliquid, paste, etc.

2. The filling machine adopts the world famous brand electrical components, low failure rate, reliable performance, long service life.

3. Contact material is stainless steel, easy to split and install, convenient to clean as to meet the requirements of GMP.

4. Simple filling volume and filling speed regulation by the touch screen display, beautiful appearance.

5. There is the function of no bottle no filling, liquid level automatic control charging. Don’t need to change parts, various specifications bottle shape can be changed very fast for no need to parts change.

6. Filling head is equipped with special blowout preventer, filling no wiredrawing, dripping phenomenon.

7.The new type filling equipment is the best choice for the realization of automatic production.

Configuration:

1. Machine Material: SUS304

2. Contact Material: SUS316

3. Rest Parts Material: rigid alumina

4. PLC Control System: Siemens

5. Touch Screen: Siemens

6. Photoelectric Sensor Components: Korea AUTONICS

7. Low-voltage Electrical Appliances: Schneider

| Technical Parameter | ||||

| Filling Volume(ml) | Productivity(b/h) | Filling Speed | Filling Precision | Air Supply |

| 10-50 | 1500-3500 | Adjustable | ≤ ± 1% | 0.4-0.8MPa |

| 80-300 | 1500-3000 | Adjustable | ≤ ± 1% | 0.4-0.8MPa |

| 100-500 | 1500-2500 | Adjustable | ≤ ± 1% | 0.4-0.8MPa |

| 300-1000 | 1500-2500 | Adjustable | ≤ ± 1% | 0.4-0.8MPa |

| 1000-5000 | 1000-2000 | Adjustable | ≤ ± 1% | 0.4-0.8MPa |

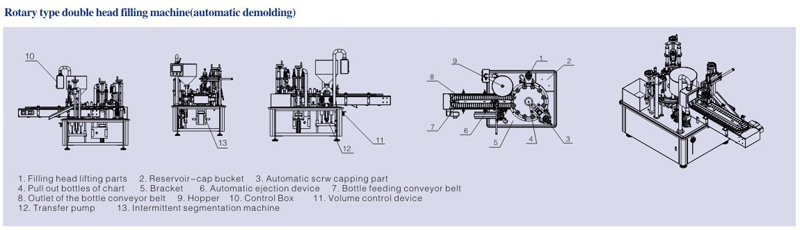

Rotary type double head filling machine(Automatic Demolding)

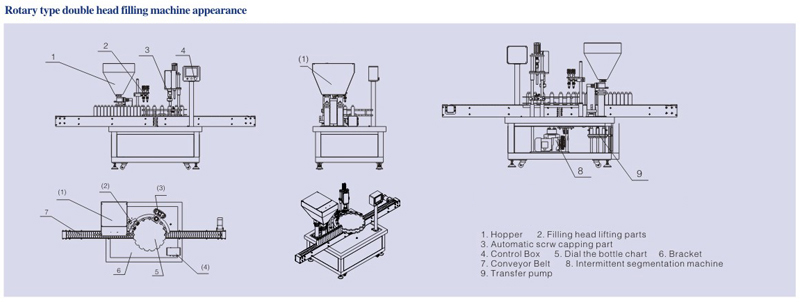

Rotary Type Double Head Filling Machine Appearance

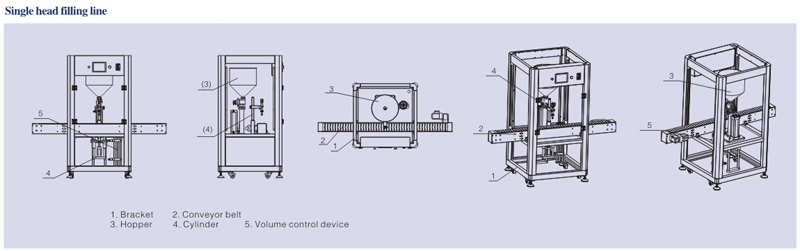

Single Head Filling Line

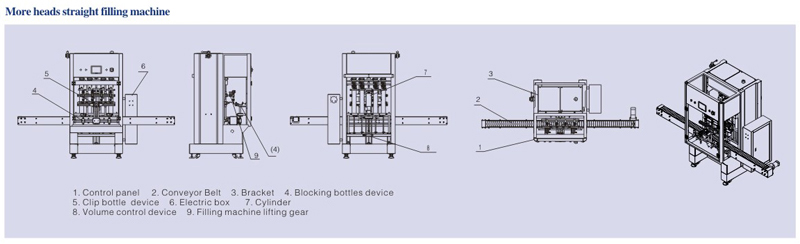

More Heads Straight Filling Machine

TVF-SL-Four Heads Automatic Paste & Liquid Filling Machine

TVF-SL Two Heads Automatic Paste Filling Machine & Feed Bottle Machine

TVF-SL-Single Head Automatic Paste Filling Machine

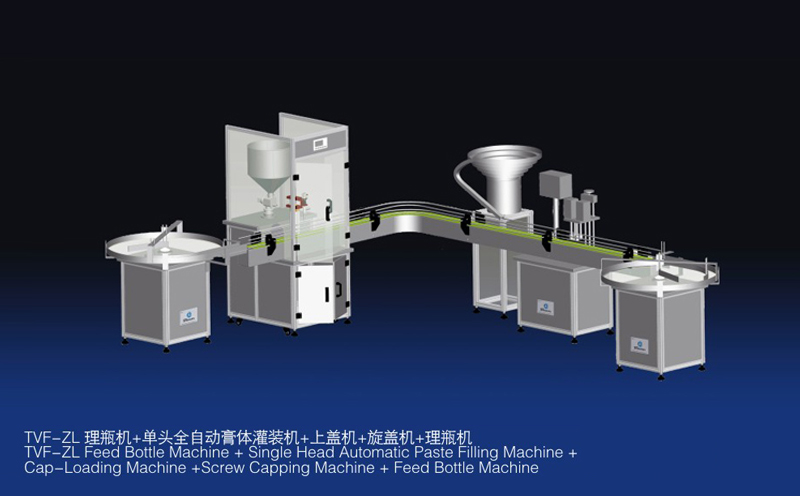

TVF-ZL Feed Bottle Machine & Single Head Automatic Paste Filling Machine & Cap-Loading Machine & Screw Capping Machine + Feed Bottle Machine

TVF-ZL Feed Bottle Machine & Single Head Automatic Paste Filling Machine & Cap-Loading Machine & Screw Capping Machine + Feed Bottle Machine

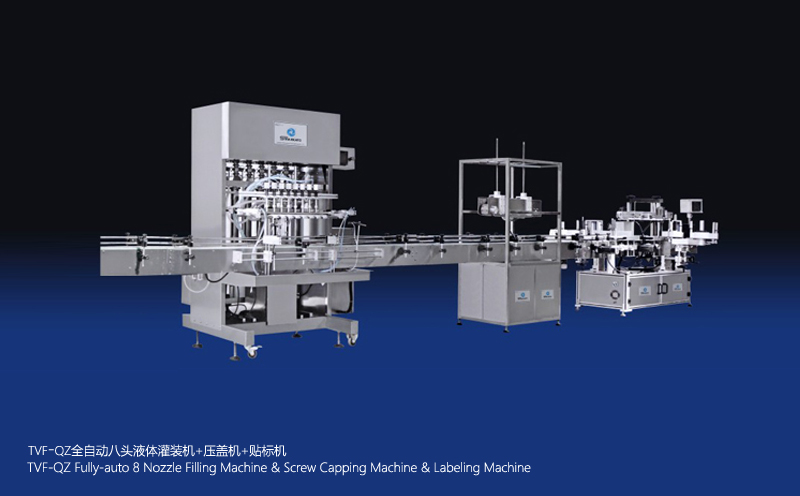

TVF-QZ Fully-Auto 8 Nozzle Filling Machine & Screw Capping Machine & Labeling Machine

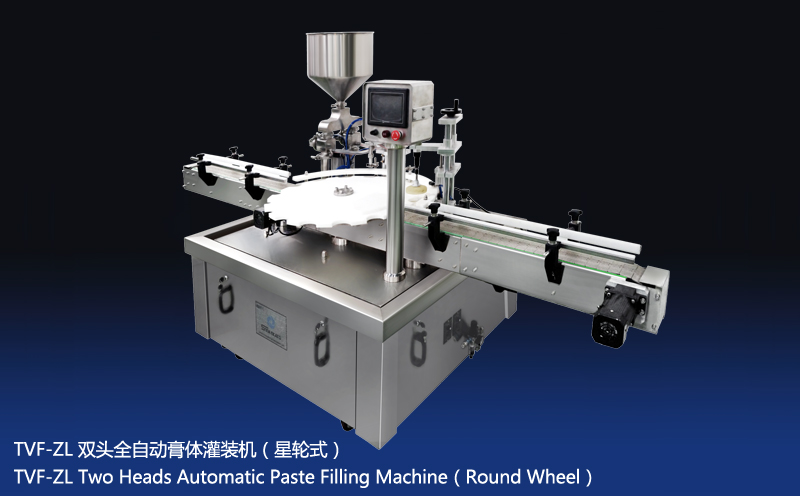

TVF-ZL-Two Heads Automatic Paste Filling Machine(Round Wheel)

TVF-SL Four Heads Automatic Paste & Liquid Filling Machine