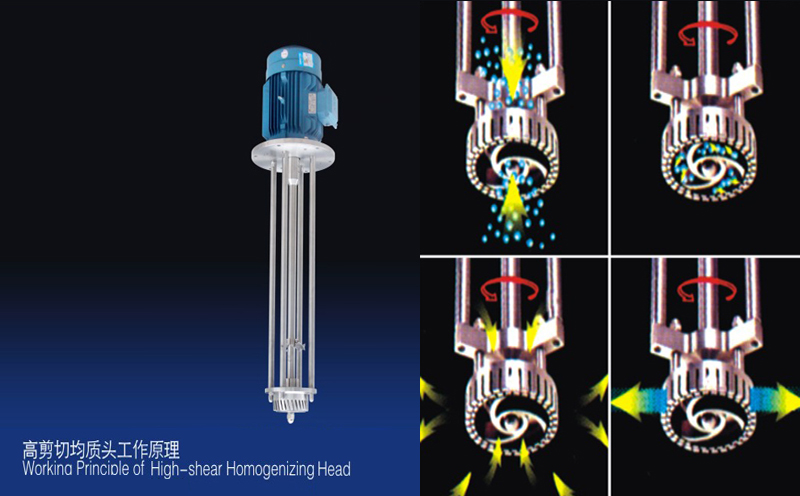

The high-shear dispersing emulsifier is to distribute one phase or more to another continuous phase in a highly-efficient, rapid and even way. Generally, the phases are mutually indissoluble. The materials will be processed in the narrow space between stator and rotor by high tangential speed and strong energy of motion respectively produced by fast- turning rotor and high frequency mechanical effect. By the operation of intensive shearing, centrifugal extruding, liquid layer attrition, impacting and breaking, and even turbulence, the materials of mutually indissoluble solid phase, liquid phase and gas phase will be refined, dispersed and emulsified instantly with the help of mature technology and proper amount of additive. After high frequency reciprocating circulation, products of stable quality are achieved.

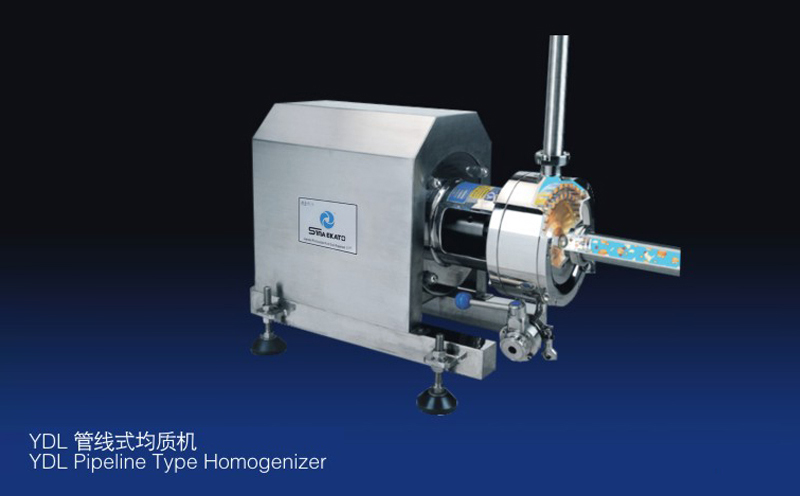

Features of pipeline type high-shear dispersing emulsifier

1. Having large disposing volume and be suitable for on-line industrialized continuous production. 2. Narrow particle size distribution range and high evenness.

3. Time saving, high efficiency and energy saving.

4. Low noise and stable operation.

5. Eliminating quality differences among the production batches.

6. The material sucking vent of homogenizer can directly suck some of raw materials into the rotor and stator for shearing and then make them flow outside the pump body.

7. Making 100% of the materials sheared and dispersed without any undispersed materials.

8. Having the transportation function of short distance and low-lift.

9. Easy in operation and convenient in maintenance.

10. The automatic control can be realized.

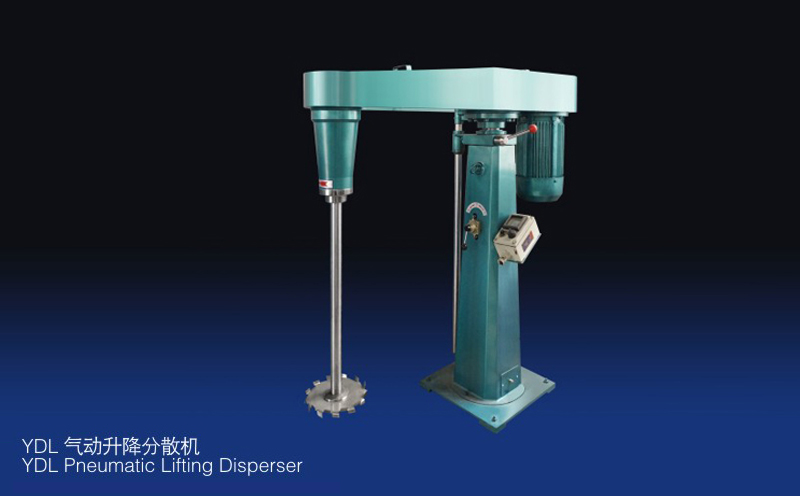

High Shearing Homogenizer-YDL Pneumatic Lifting Disperser

-1.jpg)

High Shearing Homogenizer-YDL Moveable Pneumatic Lifting Homogenizer(Stainless Steel Bracket)

.jpg)

High Shearing Homogenizer-YDL Moveable Pneumatic Lifting Homogenizer(A3 Bracket)

.jpg)

High Shearing Homogenizer-YDL Moveable Pneumatic Lifting Disperser(A3 Bracket)

High Shearing Homogenizer-YDL Moveable Hanging Homogenizer

High Shearing Homogenizer-Working Principle of High-Shear Homogenizing Head

High Shearing Homogenizer-Pipeline Type Homogenizer

High Shearing Homogenizer-Diversified Homogenizer

High Shearing Homogenizer-Bottom-Mounted Homogenizer

High Shearing Homogenizer Details of the figure