Product introduction

It adopts the method of double – bit rotation method, one person puts bottle another one colletcs bottle; The machine is divided into up and down position, with high pressure water sprinkling bottle outside and inside of the bottle. A total of two high pressure water washing, the first line using tap water, then by the high pressure gas for taking away a part of the water, after then adopts pure water/alcohol rinse; Finally with high pressure gas to take away a part of the bottle water

Auto Grade:Automatic

Advantage:Put the inverted bottles on the mould by manual. The machine adopts batch-type positioning, washing inside and outside of the bottle, ensuring that the high pressure water column sprinkle in the bottle precisely.

1.Wash the bottle with tap water in the first time.

2.Blow the bottle with air in the second time.

3.Wash the bottle wit pure water(alcohol) in the third time.

4.Blow the bottle with air in the fourth time.

Feature

1.Put the inverted bottles on the mould by manual. The machine adopts batch-type positioning,washing inside and outside of the bottle, ensuring that the high pressure water column sprinkle inthe bottle precisely. The machine is equipped with two water separator, a water pump and circulating water tank. Firstly, the machine cleans the bottle by tap water, secondly, clean by air,thirdly,cleans by pure water (alcohol), finally, cleans by air.

2.Frequency control is available and water output is adjustable according to the different bottle shape. Water control effect is good.

3.Easy operation and high efficiency

4.It is the best choice for cleaning bottles in cosmetic, pharmaceuticals and food industries.

Technical Parameter

Flushing water nozzles: 48

Working efficiency: 2000-3000blts/h

Motor power: 1.25KW/220V/frequency control

Suitable bottle height: 50-150mm

Suitable bottle diameter: 25-80mm

Water consumption: 1.55m ³/h

Flushing bottle pressure: 0.2-0.4MPa

Weight: 330kg

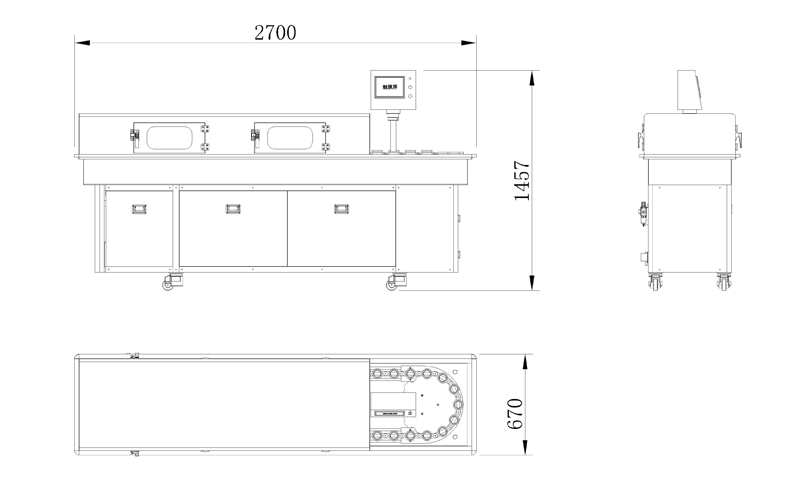

Dimension: 2700×670×1180mm(L*W*H)

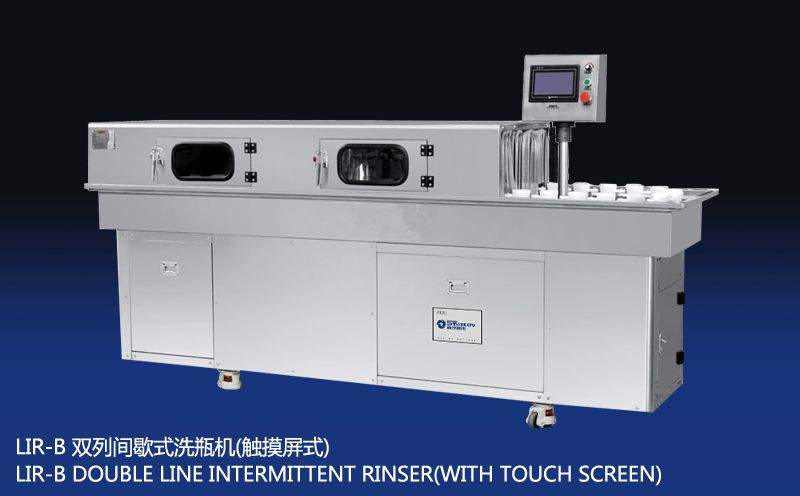

Details LIR-B Double Line Intermittent Rinser(With Touch Screen)

Planar 3D graph of LIR-B Double Line Intermittent Rinser(With Touch Screen)

LIR-B Double Line Intermittent Rinser(With Touch Screen)