The product’s manufacturing standard is divided into medical grade, corrosion resistant, sludge type and three series. In the structure, high pressure, high viscosity, high pressure and low viscosity, two manufacturing; According to the product application field is divided into ordinary grade, food grade, chemical, oil field type, special type of five classes, the core of the product components and sealing device, according to the different characteristics of different medium, different material and different forms of seal manufacturing, in order to satisfy all kinds of materials and production process, improve the performance of the professional delivery of the product.

The products are widely used in petrochemical industry, fine chemical industry, daily chemical, chemical fiber, pharmacy, food, pesticides, fertilizers, environmental protection, paper making, paint, resin, ink, and metallurgical industries, in the application of replace imported pumps kind of got the user’s consistent high praise.

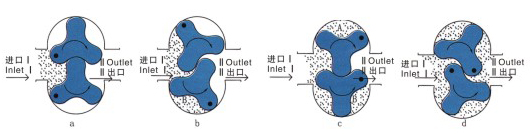

Working Principle

The rotator pump is also called as colloid pump, trefoil pump, sole pump etc. During the rotation of the two rotors (gear number is 2-4) which make synchronous reverse rotation, the rotor pump produces (vacuum degree) suction at the inlet, so as to suck the materials to be transported. The two rotors separate the rotor chamber into several small spaces and rotate according to the sequence of a—b—c—d. When rotating to position a, only chamber I is filled with media; when reaching position b,chamber B also includes some media; when reaching position c, chamber A is also filled with media; when reaching position d, chambers A, B and II will connect with each other and the media will be transported to the discharging vent. The media (materials) will be continuously transported by repeating the above operation.

Working Principle of Transfer Pump

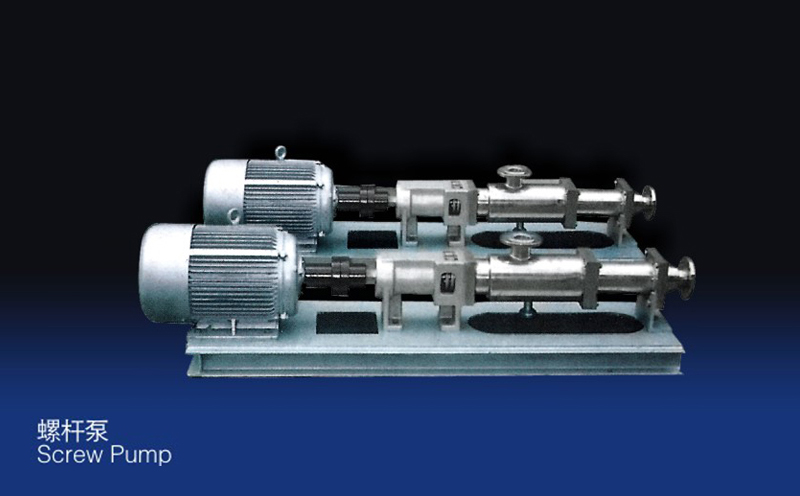

Transfer Pump-Screw Pump

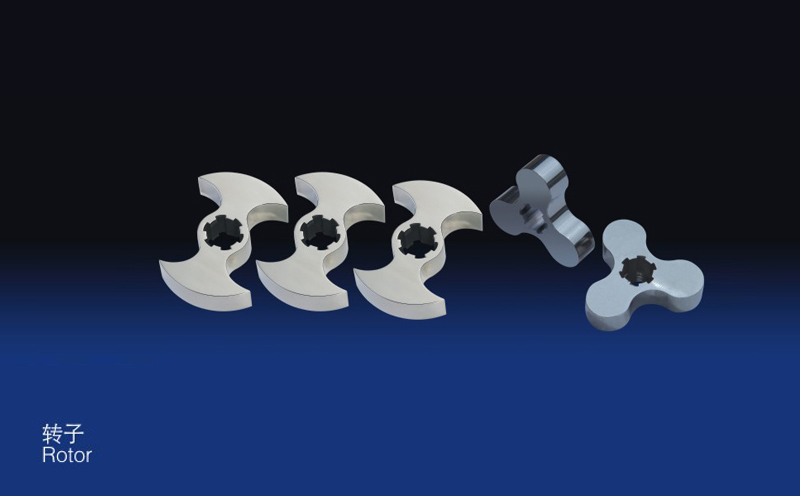

Transfer Pump-Rotor

Transfer Pump-Rotor Pump

Transfer Pump-Pneumatic Diaphragm Pump

Transfer Pump-Centrifugal Pump